-

European Pine

European Pine

-

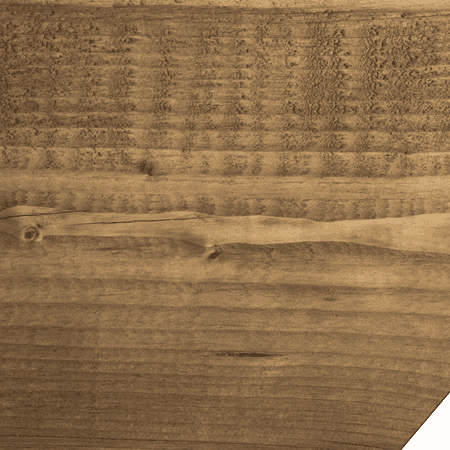

Western Red Cedar - Knotty

Western Red Cedar - Knotty

-

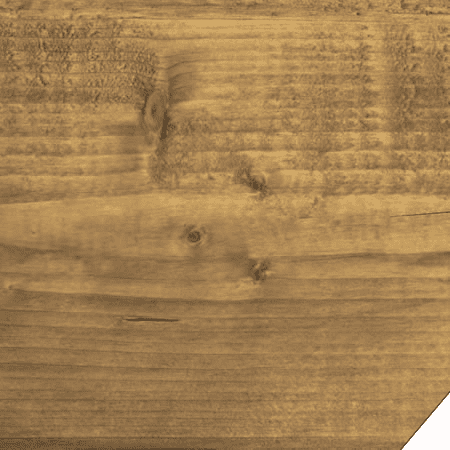

Redwood

Redwood

-

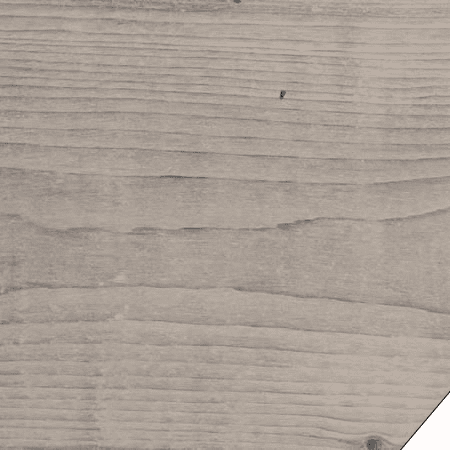

Pressure Treated Southern Yellow Pine

Pressure Treated Southern Yellow Pine

-

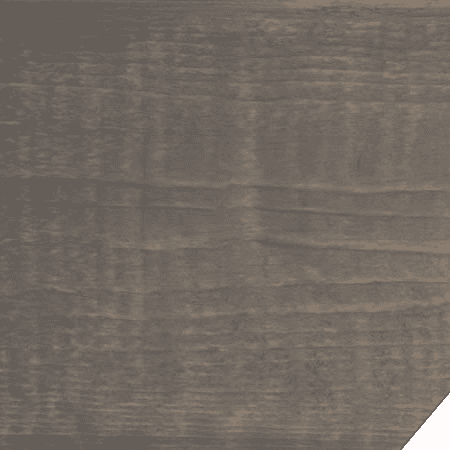

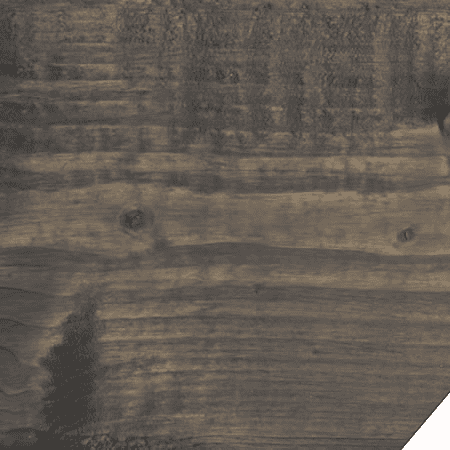

Pressure Treated (brown)

Pressure Treated (brown)

-

IPE

IPE

-

Douglas Fir - Smooth

Douglas Fir - Smooth

Cutek Extreme Premium Wood Protection in Canada

Protect your deck, fence and exterior wood with Cutek Extreme, trusted across Canada for unmatched durability and weather resistance. Fast shipping, expert advice, and everything you need for a flawless finish.

$129.99

Unit price

/

Unavailable

Shipping calculated at checkout.

Cutek Extreme Exterior Wood Protection Oil - 3.60L (0.95 US Gallon) is backordered and will ship as soon as it is back in stock.

The Ultimate Deck Shop

| SKU:

210000001025

$44.99

Unit price

/

Unavailable

Shipping calculated at checkout.

Cutek Extreme Brushes Bundle is backordered and will ship as soon as it is back in stock.

Cutek Colourtone

Add Colourtone tint to add beauty and UV protection. Minimum 1 tint per gallon - for more vibrant colour, add 2 tints per gallon!

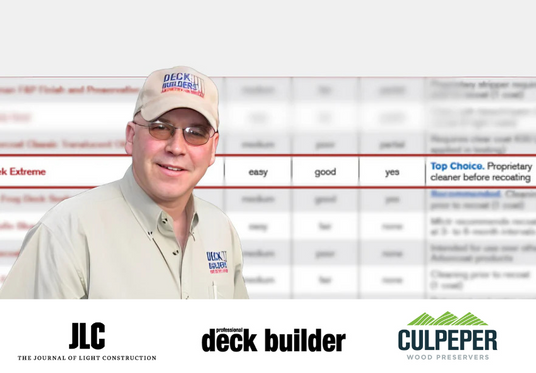

Award-Winning Wood Protection Solution

CUTEK Extreme emerges victorious in a rigorous 29-month study, outperforming 26 competitors as the top choice for exterior wood protection. This revolutionary product works on any wood, under any conditions, providing unmatched defense against moisture, mold, and weathering

We've Curated the Best, You Choose What's Right for You

Since 2021, we have shipped thousands of gallons of Cutek Extreme to customers just like you who were frustrated with their current deck stain!

Select a Colourtone For Your Project

Colourtone Options

Colourtone swatches are shown below in groups of Brown Hues, Red Hues, Yellow Hues and White/Black Hues.

Single Strength

Clear

Single Strength

Double Strength

Espresso

Single Strength

Double Strength

Ashwood*

Single Strength

Double Strength

Pecan

Single Strength

Double Strength

Walnut

Single Strength

Double Strength

Bark

Single Strength

Double Strength

Cedartone

Single Strength

Double Strength

Terra Cotta*

Single Strength

Double Strength

Autumntone

Single Strength

Double Strength

Burnt Red*

Single Strength

Double Strength

Light Oak*

Single Strength

Double Strength

Goldtone

Single Strength

Double Strength

Honeycomb

Single Strength

Double Strength

Rustic Gold

Single Strength

Double Strength

White Wash*

Single Strength

Double Strength

Smokey Grey

Single Strength

Double Strength

Blue Slate*

Single Strength

Double Strength

Graphite Grey

Single Strength

Double Strength

Black Ash

Single Strength

Clear

Single Strength

Double Strength

Espresso

Single Strength

Double Strength

Ashwood*

Single Strength

Double Strength

Pecan

Single Strength

Double Strength

Walnut

Single Strength

Double Strength

Bark

Single Strength

Double Strength

Cedartone

Single Strength

Double Strength

Terra Cotta*

Single Strength

Double Strength

Autumntone

Single Strength

Double Strength

Burnt Red*

Single Strength

Double Strength

Light Oak*

Single Strength

Double Strength

Goldtone

Single Strength

Double Strength

Honeycomb

Single Strength

Double Strength

Rustic Gold

Single Strength

Double Strength

White Wash*

Single Strength

Double Strength

Smokey Grey

Single Strength

Double Strength

Blue Slate*

Single Strength

Double Strength

Graphite Grey

Single Strength

Double Strength

Black Ash

Single Strength

Clear

Single Strength

Double Strength

Espresso

Single Strength

Double Strength

Ashwood*

Single Strength

Double Strength

Pecan

Single Strength

Double Strength

Walnut

Single Strength

Double Strength

Bark

Single Strength

Double Strength

Cedartone

Single Strength

Double Strength

Terra Cotta*

Single Strength

Double Strength

Autumntone

Single Strength

Double Strength

Burnt Red*

Single Strength

Double Strength

Light Oak*

Single Strength

Double Strength

Goldtone

Single Strength

Double Strength

Honeycomb

Single Strength

Double Strength

Rustic Gold

Single Strength

Double Strength

White Wash*

Single Strength

Double Strength

Smokey Grey

Single Strength

Double Strength

Blue Slate*

Single Strength

Double Strength

Graphite Grey

Single Strength

Double Strength

Black Ash

Single Strength

Clear

Single Strength

Double Strength

Espresso

Single Strength

Double Strength

Ashwood*

Single Strength

Double Strength

Pecan

Single Strength

Double Strength

Walnut

Single Strength

Double Strength

Bark

Single Strength

Double Strength

Cedartone

Single Strength

Double Strength

Terra Cotta*

Single Strength

Double Strength

Autumntone

Single Strength

Double Strength

Burnt Red*

Single Strength

Double Strength

Light Oak*

Single Strength

Double Strength

Goldtone

Single Strength

Double Strength

Honeycomb

Single Strength

Double Strength

Rustic Gold

Single Strength

Double Strength

White Wash*

Single Strength

Double Strength

Smokey Grey

Single Strength

Double Strength

Blue Slate*

Single Strength

Double Strength

Graphite Grey

Single Strength

Double Strength

Black Ash

Single Strength

Clear

Single Strength

Double Strength

Espresso

Single Strength

Double Strength

Ashwood*

Single Strength

Double Strength

Pecan

Single Strength

Double Strength

Walnut

Single Strength

Double Strength

Bark

Single Strength

Double Strength

Cedartone

Single Strength

Double Strength

Terra Cotta*

Single Strength

Double Strength

Autumntone

Single Strength

Double Strength

Burnt Red*

Single Strength

Double Strength

Light Oak*

Single Strength

Double Strength

Goldtone

Single Strength

Double Strength

Honeycomb

Single Strength

Double Strength

Rustic Gold

Single Strength

Double Strength

White Wash*

Single Strength

Double Strength

Smokey Grey

Single Strength

Double Strength

Blue Slate*

Single Strength

Double Strength

Graphite Grey

Single Strength

Double Strength

Black Ash

Single Strength

Clear

Single Strength

Double Strength

Espresso

Single Strength

Double Strength

Ashwood*

Single Strength

Double Strength

Pecan

Single Strength

Double Strength

Walnut

Single Strength

Double Strength

Bark

Single Strength

Double Strength

Cedartone

Single Strength

Double Strength

Terra Cotta*

Single Strength

Double Strength

Autumntone

Single Strength

Double Strength

Burnt Red*

Single Strength

Double Strength

Light Oak*

Single Strength

Double Strength

Goldtone

Single Strength

Double Strength

Honeycomb

Single Strength

Double Strength

Rustic Gold

Single Strength

Double Strength

White Wash*

Single Strength

Double Strength

Smokey Grey

Single Strength

Double Strength

Blue Slate*

Single Strength

Double Strength

Graphite Grey

Single Strength

Double Strength

Black Ash

Single Strength

Clear

Single Strength

Double Strength

Espresso

Single Strength

Double Strength

Ashwood*

Single Strength

Double Strength

Pecan

Single Strength

Double Strength

Walnut

Single Strength

Double Strength

Bark

Single Strength

Double Strength

Cedartone

Single Strength

Double Strength

Terra Cotta*

Single Strength

Double Strength

Autumntone

Single Strength

Double Strength

Burnt Red*

Single Strength

Double Strength

Light Oak*

Single Strength

Double Strength

Goldtone

Single Strength

Double Strength

Honeycomb

Single Strength

Double Strength

Rustic Gold

Single Strength

Double Strength

White Wash*

Single Strength

Double Strength

Smokey Grey

Single Strength

Double Strength

Blue Slate*

Single Strength

Double Strength

Graphite Grey

Single Strength

Double Strength

Black Ash

Start your project here

-

Cutek

Cutek Wood Reviver (ProClean Deck Restoration)

$79.99Unit price /UnavailableLow stock (8 units) -

-

Escape TO not FROM your Backyard

Save time and money on your favourite products whenyou subscribe.

- Curated selection of top-quality wood protection products

- Expert advice to help you choose the right solution

- Competitive pricing on all CUTEK products

- Fast Delivery / FREE Delivery for orders over $199 (excludes oversized items)

Frequently Asked Questions

Is Cutek Extreme worth it?

Is Cutek Extreme worth it?

Yes, CUTEK Extreme is worth the investment. It was voted the "top choice" in a comprehensive nine-month study comparing 21 wood protection products. It outperformed competitors in moisture content, mold resistance, weathering, and color retention tests. Many wood industry professionals and homeowners appreciate its long-lasting protection and its ability to enhance the natural beauty of wood.

How long does it take for CUTEK extreme to dry?

How long does it take for CUTEK extreme to dry?

CUTEK Extreme typically takes 24 to 72 hours to dry completely, depending on temperature and humidity. For best results, allow at least 24 hours between coats. Ensure the wood feels dry to the touch before applying additional layers.

How to use CUTEK Extreme?

How to use CUTEK Extreme?

To use CUTEK Extreme, apply thin, even coats with a brush or paint pad, as it works best when applied as a thin coat. For optimal results, use two or three thin coats on finished wood instead of one or two thick coats. Allow 24-72 hours for each coat to dry before applying the next.

What if it rains after applying CUTEK?

What if it rains after applying CUTEK?

Avoid application if rain is expected within 48 hours. Cold temperatures can increase the oil's viscosity, slowing down diffusion and drying time. For best results, apply when dry weather is forecast and temperatures are moderate.

What are the disadvantages of decking oil?

What are the disadvantages of decking oil?

Decking oils offer protection but won't conceal damaged wood or significantly alter the appearance of existing decking. They provide a translucent finish, allowing the natural texture and grain of the wood to remain visible, even with tinted oils.

Is decking oil better than protector?

Is decking oil better than protector?

Decking protector absorbs into the water, creating a translucent, water-proof layer. Decking stain, on the other hand, comes in a variety of colours, as well as weather-proofing the wood. Decking oils replaces the woods natural oils, while leaving a subtle colour.

How long does it take for CUTEK extreme to dry?

How long does it take for CUTEK extreme to dry?

CUTEK® Extreme is a high-performance, oil-based wood stabilizer. It has been designed to protect wood from the inside out while allowing it to gradually fade over time without peeling, cracking or splitting.

What is CUTEK extreme made of?

What is CUTEK extreme made of?

CUTEK extreme is made of synthetic oils and resins that penetrate deeply into wood, providing long-lasting protection against moisture and UV damage.